ST-918-B-1 Wire stripper

- Category: Wire stripping machine

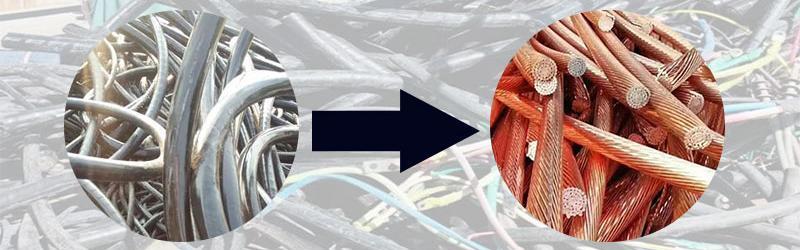

Large wire stripping machine is an industrial-grade automated equipment designed for efficient stripping of insulation or sheath of large-size cables (such as power cables, communication optical cables, automotive wiring harnesses, etc.). It is characterized by strong processing capacity and high degree of automation,and is suitable for large-volume, high-intensity continuous production environments.

Model

ST-918-B-1

Power

5.5KW

Net Weight

250KG

Wire Range

2-160MM

Dimensions

970*600*1300mm

Structural composition

1. Cutter head system: High-strength cutter head, capable of cutting thick cables with a diameter of more than 50 mm, and supports layer-by-layer stripping of multiple layers of insulation(such as outer skin, shielding layer, and insulation layer).

2. Wire feeding mechanism: Rollers or clamps fix the cables to ensure stable wire feeding during stripping.

3. Adjustment device: supports flexible adjustment of wire diameter, stripping length, and stripping depth, and is suitable for wires of different specifications (such as 0.1–6 mm²).

4.Drive system: High-power motor, providing high-strength cutting power, suitable for hard materials such as metal armored wires.

Advantages

1. High productivity: greatly reduce the unit wire processing time and improve the overall efficiency of the factory.

2. Strong adaptability: can handle a variety of wires from ultra-fine coaxial cables to heavy armored cables.

3. High precision and stability: error ≤ 0.05 mm, ensuring the consistency of mass production.

4. Long life design: wear-resistant alloy blades and dust-proof structure are used, suitable for 24-hour continuous operation.

Purchase suggestions

1. Capacity requirements: Choose a single machine or multi-machine linkage solution based on the production scale.

2. Wire diameter range: Confirm the maximum/minimum wire diameter that the equipment is compatible with.

3. Energy consumption and maintenance: Large equipment needs to pay attention to power requirements (such as three-phase power).

Services

1. OEM and ODM customization available

2. Controllable delivery time

3. Ensured stable quality

4. Regular technical updates

5. Technical training sessions for operators

6. 24/7 customer service availability

After-sales Support

1. Provision of test videos before delivery

2. Video-guided installation

3. Free replacement parts

4. One-year warranty

5. Lifetime technical support

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Ian Smith

Mobile:+86 19991805031

Tel:+86 19991805031

Whatsapp:8619991805031

Email:ian@strykermachinery.com

Add:Room 1002, Building 10, District 2, Duyong Village, Changxiang Street, Chang'an District, Xi'an, Shanxi Province